Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Thursday March 15, 2007

Left Wing Drilling, Tapped Tie Downs

(Wings)

3.0 Hours

| Previous - Index - Next |

I clecoed the left wing together tonight and match drilled all of the main ribs to the two spars.

And the five outboard leading edge ribs.

I deburred all of these freshly drilled holes.

Tapping is the process of taking a solid-walled hole and creating bolt/screw threads inside of it suitable for threading a bolt or screw into. You slowly turn the appropriately sized cutter into the hole and it cuts out the spiral groves that form the threads.

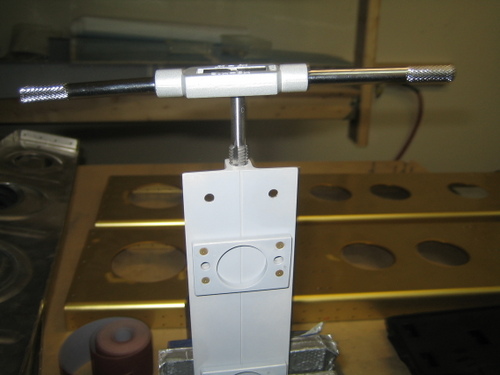

I had ordered a nice, cheap tap & die set from Harbor Freight a while back when I was working on these tie down bars. I still needed to tap the 3/8-16 screw holes. I've never tapped anything before, but I found some instructions on technique and went from there. I turned a 1/2 turn forward, a 1/4 back, then a 1/2 forward, and repeated that to the 1" depth called out in the plans.

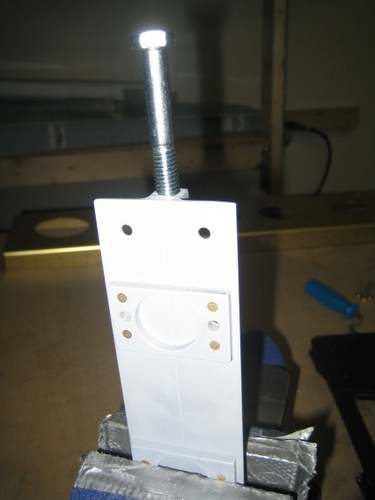

Both holes came out very nicely. I threaded this 3/8-16 steel bolt into them to make sure they worked.

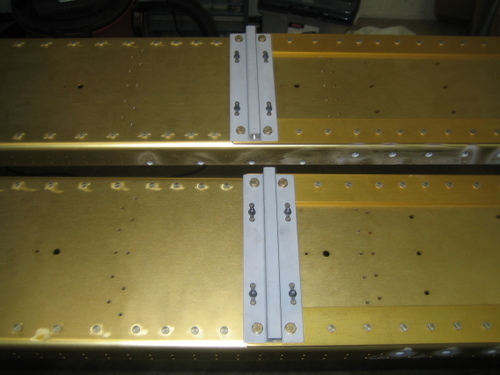

Then, I torqued the tie down bars onto the main spars. The plans have you attach the aileron bellcrank brackets now as well (they get bolted into those nutplates you see here), but I noticed on Dan Checkoway's page that he had to take them off again later. I'll hold off on those.

Next up: prepping and priming all of these wing ribs and building my wing jig.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International