Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Wednesday June 25, 2008

Aileron Bending, Skeleton Drilling

(Ailerons)

1.5 Hours

| Previous - Index - Next |

Tonight, I spent about an hour cleaning the shop--it was filthy. A clean, organized shop helps me think more clearly.

Then, I built my new bending brake out of some 2x8's and a plethora of hinges. The aileron skins came out very well, I think. I started with small radius dowel in the trailing edge and then removed it to get the finished bend.

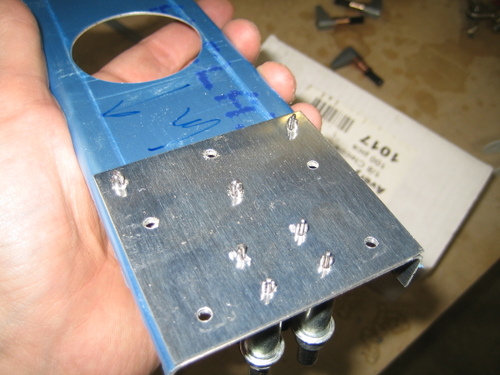

Then, I started working on the aileron spar. The instructions have you match drill these little reinforcement plates to the spar. The perspective in this photo makes it look like the plate is mis-aligned, but it's right where it's supposed to be.

Then, I drilled the steel hinge brackets to both ends using a #12 bit. It took me about 10 minutes of head scratching and prolonged drilling to realize that the #12 bit I was using was exceedingly dull. It simply would not punch through the steel. I tossed it and switched to another bit and it ate through like butter.

I couldn't find any mention of this problem anywhere, but, unless I'm missing something, my aileron drawings don't call out what goes in the two #40 holes that sit underneath the hinge brackets on both ends of the ailerons. I'm going to assume that these are AN426-4 flush rivets and go with that. I'm pretty sure I'll dimple for these, rather than countersink.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International