Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Saturday December 13, 2008

Firewall Layout, Drilling

(Firewall)

5.2 Hours

| Previous - Index - Next |

After fabbing the first F-601J by hand with the hack saw, I decided it was time for a band saw. Here's one I picked up for cheap at Lowes. It works fine and, with a 18 TPI blade, cuts through aluminum like butter. This will save me so much time.

Today, I fabricated the other F-601J and continued laying things out and drilling holes to final size.

Here's the left F-601J drilled to the angles. To drill these, you clamp things together and back-drill through the firewall.

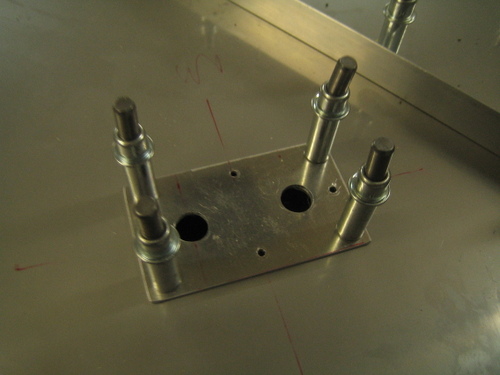

Here's the F-601TD reinforcement plate where the brake lines will come through the firewall. I couldn't find the right piece of AS3-063 to make this from, so I stole some from something else. It came out ok...the 5/8" holes are a little bit (1/32") off of ideal alignment. The unibit worked great for enlarging the holes in the steel firewall, though.

After things were drilled, the assembly came apart for deburring, countesinking, and priming. Here's the firewall all deburred. Deburring the edges of the steel took a lot more work than the aluminum does. Tomorrow, I'll dimple the firewall holes (the forward side of the firewall needs to be flush).

I'm in the process of deburring the edges of the angle. Most of these holes will also be countersunk where they will sit against dimples in the firewall.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International