Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Saturday June 6, 2009

F-705 Bulkhead Drilling, Deburring, Riveting

(Bulkheads)

3.0 Hours

| Previous - Index - Next |

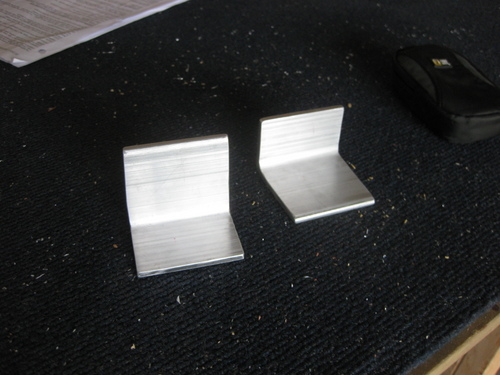

I started by finishing off these angles for the F-705. I think they're F-705G's. They had to be trimmed to specs.

Then, I got back to work on the other F-705 pieces that I had screwed up so long ago. These pieces have to be bent at a four degree angle.

I clamped them between the table and a piece of wood, then used my back-riveting plate clamped to the free side to affect the bend.

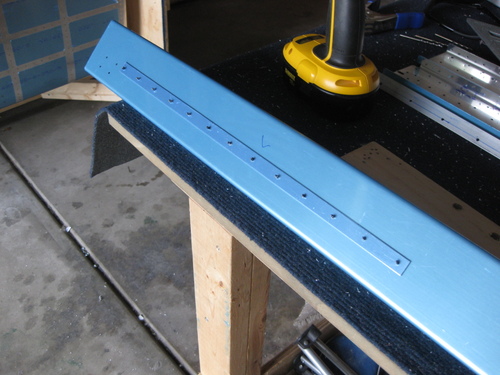

Next, I drilled these angle pieces to the top F-705 piece, using 1/8" drill bits to get the spacing right.

I drilled the shims, using the bulkhead piece as a guide.

Then I drilled the angle piece to the shim and cleco'd everything together to see how it fits. I really have no idea what the purpose of this thing is, but I think it has something to do with supporting the backs of the cockpit seats.

I then took all of these pieces apart and deburred them. I also countersunk the angled pieces to accept the flush rivets. While the primer on the angles was drying, I riveted the angle pieces and shims to the F-705 top piece.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International