Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Thursday August 31, 2006

HS Front & Rear Spars

(Horizontal Stabilizer)

2.5 Hours

| Previous - Index - Next |

At lunch time yesterday I fired up the air compressor and final drilled the rear spar to the rear spar stiffeners. Then I pulled out the elevator hinge brackets, clecoed them to the rear spar, and final drilled all but the two in the center. I clecoed and clamped the elevator hinge bearing between the two center brackets and match drilled the holes that hold that assembly together.

After listening to Dan Checkoway talk about priming at the workshop, I decided to use rattle can self-etching primers for my plane. With most of the aluminum parts being Alclad, it doesn't seem like I need to go crazy with the priming. The rattle cans are quick, easy, and make short work of the cleaning process. I will probably prime primarily the mating surfaces of Alclad aluminum and 100% of the non-Alclad parts.

When I got off work, I went to Benton Harbor and visited a couple of places to see if I could find the Sherwin Williams GBP 988, the Mar-Hyde, or the NAPA 7220 varieties of primers. No luck...the NAPA store could special order the primer if I wanted and nobody knew about the other two. I'll be calling around today to see if I can find them.

I did buy one can of the generic brand that everyone has, called "Dupli-Color". I tested it on a piece of scrap and the result seemed "ok" to me.

However, I'm not a painting or priming expert and I want to get something that has a proven track record on previous RVs, so I'll wait until I find one of the brands I talked about.

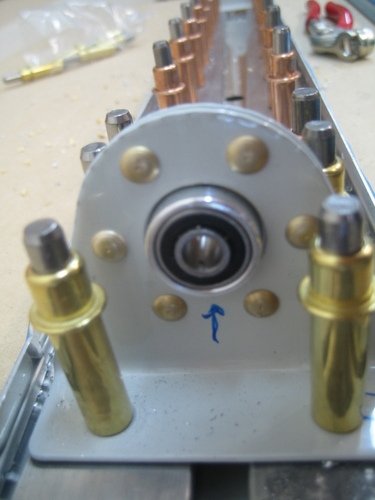

After a visit to Lowes for some miscellaneous items, I got back to work on the HS. I riveted the center hinge bracket and bearing assembly together with the pneumatic squeezer. The rivets came out fairly consistently, but they were not perfectly straight. I think it may have had something to do with how I had the assembly clamped in my vise for riveting.

I clecoed the finished product to the rear spar and drilled the bolt holes that attach it to the spar to #12 as specified. Then I pulled out the HS front spar and angle stiffeners. I clecoed the angle stiffeners to the spar and match drilled all of the holes inboard of the bend lines. Both the stiffeners and the inboard tabs on the spars will get bent to match the leading edge of the HS after I've smoothed and radiused the ends of the stiffeners and trimmed back some extra length from the spar flanges. These forward spars are actually RV-8 parts, according to the plan, and must be adapted slightly for the RV-7.

I drew some guide lines for the taper on the stiffeners and started removing material, but I was tired and quit for the night.

In occasional visits to Dan's RV-7 Project Page I've noticed that Vans is now pre-punching some parts that weren't punched before. For instance, my angle stiffeners were already match drilled to the front spar. It's nice to see them improving little things like this as they go.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International