Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Saturday April 24, 2021

Cabin Frame Roll Bar Installation

(Cabin Frame)

5.0 Hours

| Previous - Index - Next |

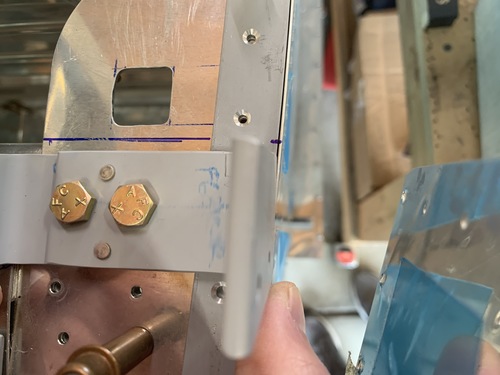

So I screwed up when I drilled the brackets to the fuselage earlier this week. The forward part of the outboard angle is supposed to be flush with the lower skin here, but I made it flush with the longeron.

I worried about this for a while, but I think it will be okay. I can always put a small spacer in this area if I don't like the way the upper skin lays.

I didn't take a picture of this part, but next I sanded down the angle brackets so they conform to the shape of the fuselage as it narrows aft.

Then, I trimmed part of the seat support on both sides as it was interfering with the inboard angle. This is a common issue.

Then, I notched the outboard part of the channel where it sits against the outboard angle piece.

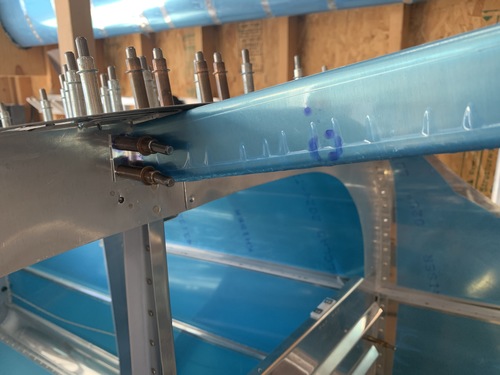

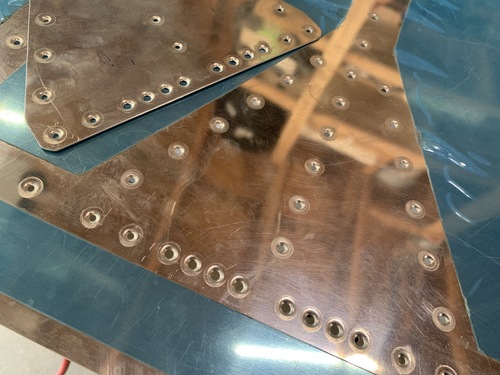

I drilled these holes that attach the top skin to the F-732A channel out to 1/8". It goes through the skin, a gusset, the bulkhead, the F-732F spacer and then finally the F-732A channel, which serves as a support for the roll bar.

I drilled these flanges to the bulkhead.

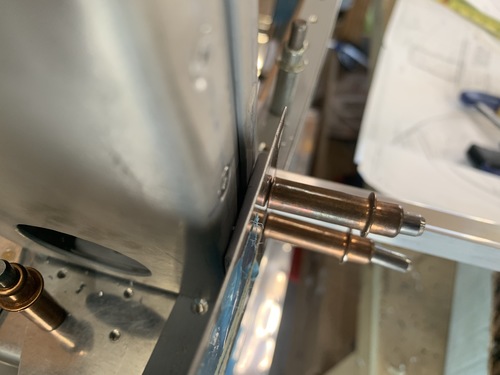

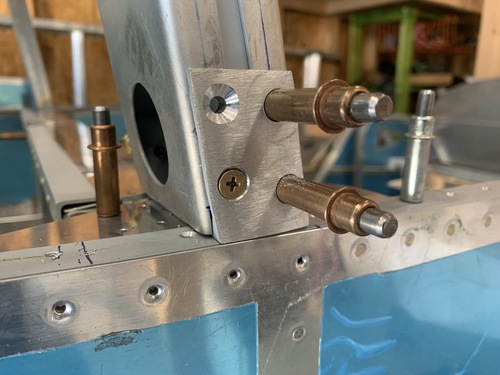

And I drilled these angles I made a while ago to the F-732A and rollbar.

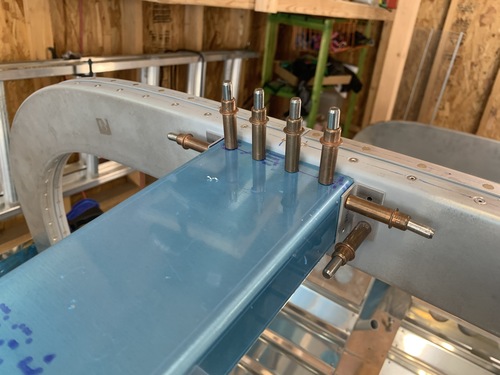

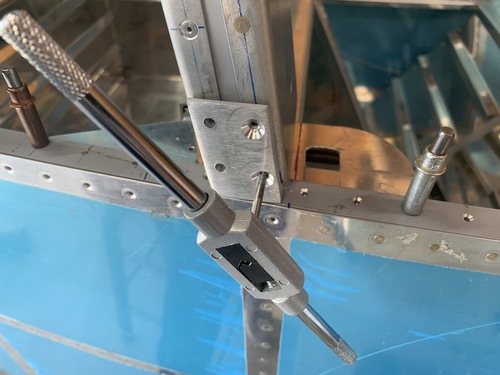

Then, I clamped the rollbar carefully in place and drilled it to the angle bracket that will connect it to the fuselage. The first two holes get drilled from the aft upper skin.

Then, I pealed back the skin and drilled the other two holes.

I also drilled the inboard holes through the rollbar into the angle that nests inside it.

I dimpled the skin, countersunk the angle, and tapped the hole for screws per the plans.

This is how it will look when it's finished, with screws through the skin.

Here's an illustration of how my error with the side-to-side positioning of the angle brackets effects things. It means the upper skin has a noticeable jog to it as it passes over the longeron. I may put a spacer in here later to make it look nicer.

Then I countersunk for these larger screws that get hidden under the skin.

I dimpled the F-774 and F-788 for those 1/8" rivets.

I countersunk F-732F.

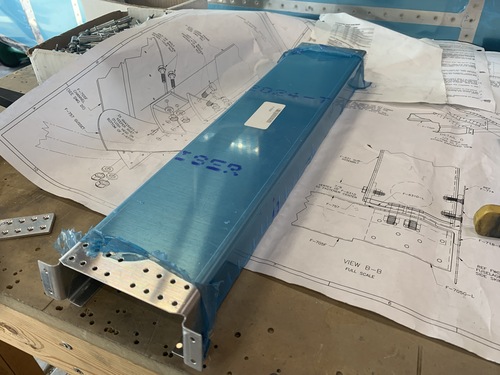

I deburred and edge-prepped the F-732A.

Then I prepped and primed the F-788, F-732E brackets, and F-732F.

I riveted F-732F to F-732A.

And I riveted the F-732E brackets to F-732A.

It looks nice and it's super stable/solid.

This is all I'll do for now on this stuff--I want to leave the aft fuselage open for now.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International