Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Tuesday January 4, 2022

Canopy Frame Drilling

(Canopy)

5.4 Hours

| Previous - Index - Next |

Today, I started by removing the frame and skin and cleaning out the loose bits of aluminum.

Then, I fit them back to the fuselage, taped them down, and drilled these holes in the weldment.

Then I took everything apart again and countersunk the holes on the forward side of the weldment.

I primed the mating surfaces.

Then I riveted the weldment together.

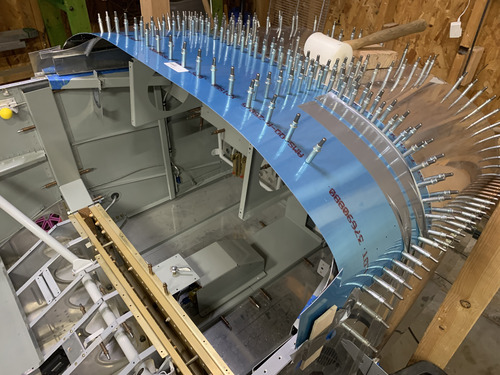

Then I reinstalled everything and taped it down really carefully. I then started the 1/4" holes through the hinges using the UHMW blocks as a guide with a 90 degree drill.

Then I took the frame off and finished drilling the holes with a block of wood as a guide to ensure the hole was straight.

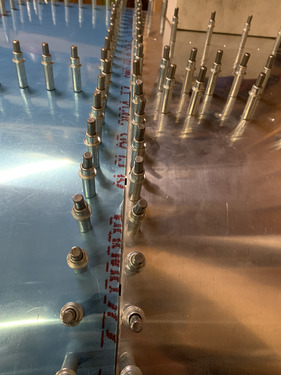

This is when things turned to shit for a while and I stopped taking pictures. Turns out even though I started drilling the bolt holes from the existing 1/4" holes, they both came out fairly misaligned. The left side made the skin a little bit too high and on the right side, I suddenly had a gap of 1/8" between the two skins (e.g. the hole was too far forward in the hinge). I was really pissed, because I did everything right. I still don't know how it turned out this way.

Anyway, the good news was that these holes still needed to be enlarged to 3/8" for the bushing, so there was a way to adjust the holes slightly. I spent some time widening the 1/4" holes in the directions that I wanted them to go so that I ended up with an oblong hole "stretched" in the right direction. This way, when I went to drill with the 3/8" bit, it would even out and the resulting hole would be shifted from the original 1/4" hole.

This ended up working okay. I was able to bring the gap on the right side between the skins down to about 1/16"--this still isn't as good as I had it before drilling the hinge, but it's a big improvement. The upward shift on the left side is still pretty apparent, though.

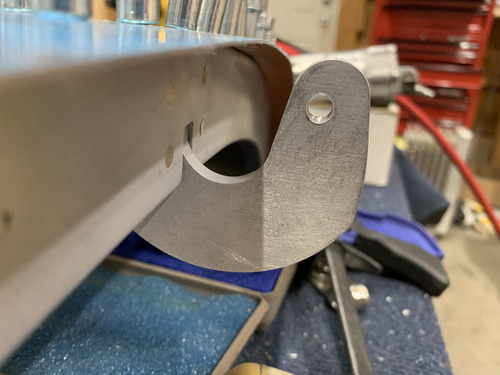

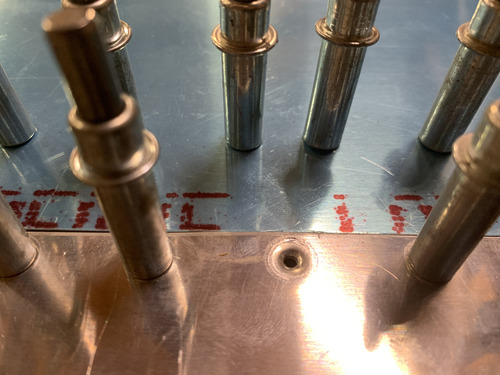

Here's that 1/16" gap on the right side. Unless something else shifts during the rest of the canopy work, I think this is how it will have to be.

And here's the bulge on the left side since this side is still a bit elevated. I should have elongated the hinge hole on this side a little further. Hopefully I can fix this with shimming and shrinking.

I spent some time filing down the seal support angles so they don't rub on the weldment when it opens.

One other problem area is right in the middle. The canopy skin wants to catch on the forward fuselage skin when you start to rotate the canopy upward. I'll have to do some filing or shimming or something here.

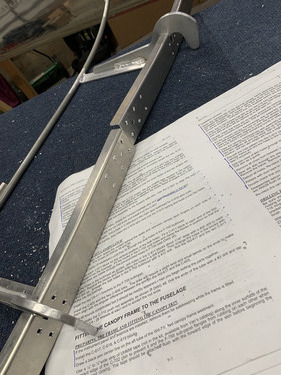

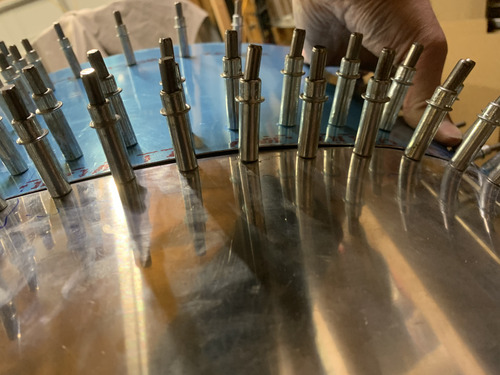

Finally, I made the 1/8" and 7/8" spacers for the next steps of the canopy frame work.

All in all a rather frustrating day. I don't know why the holes in the hinges were so out of alignment, but I'm glad I thought of a way to salvage them. The other option would be to have someone TIG weld the holes shut and re-drill them, but I'm not sure I could get them better than this.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International