Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Friday January 7, 2022

Canopy Frame Fitting & Drilling

(Canopy)

5.0 Hours

| Previous - Index - Next |

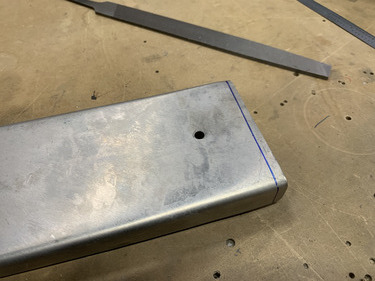

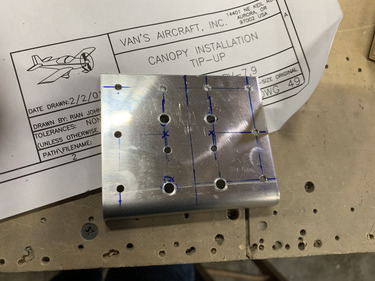

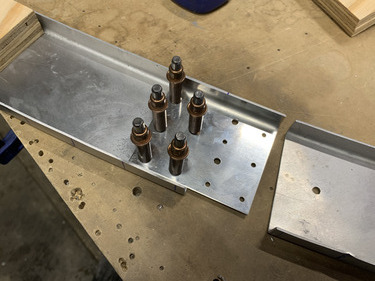

I started today by making the C-613 splice plates. I measured and drilled one and then used it to drill the other.

I spent a lot of time bending the flanges on the top of these F-631A channel flanges for approximately the required 88 degrees.

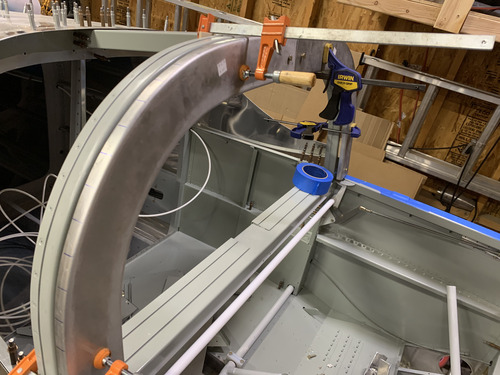

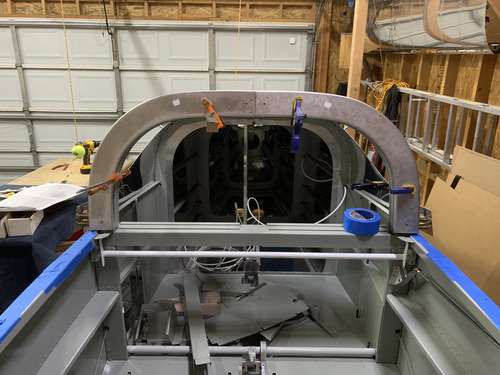

I clamped them to the roll bar with the 7/8" spacers to get an idea of the fit.

They both needed a little bit of trim off the middle.

I used the tooling holes as a guide so they would be pretty well aligned with the ones in the roll bar. The fit looks pretty good. I also marked the spots where I won't be putting the screws for the canopy, so I could flute them slightly for straightness.

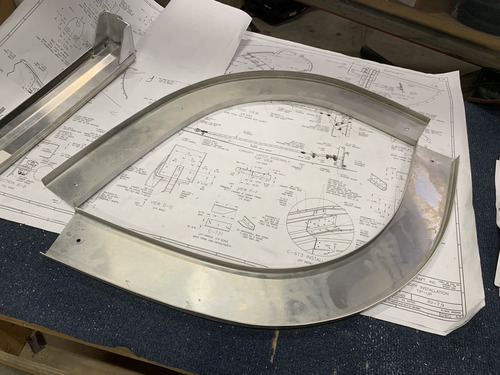

I measured and drilled the C-704 splice plate that will eventually join the two F-631A channels.

I drilled the C-704 to one of the F-631A's per the instructions. The other side will get drilled later.

Then, I clamped them carefully in place on the roll bar.

I measured and drilled the holes in the WD-725 weldment angles.

This was the area on the forward weldment that the instructions were talking about squeezing to smooth out a bend. I did that on both sides.

I carefully clamped the WD-725s in place with their 1/8" spacers. They abut the F-631A on the aft end and then will be riveted to the WD-716 at the front with the C-613 spice plates.

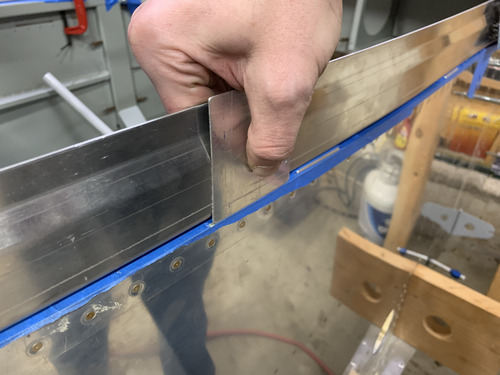

I used a piece of scrap 0.032" aluminum sheet to get the right offset from the fuselage skin. The skin that sits over the side weldments will eventually be flush with the fuselage side.

I drilled the WD-725-R to the F-631A-R.

And I drilled the WD-725-L to the F-631A-L.

Then I drilled one of the C-613s to the WD-725-L and the WD-716.

And the other one to the WD-725-R and the WD-716.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International