Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Saturday January 8, 2022

Canopy Frame Drilling, Riveting

(Canopy)

4.3 Hours

| Previous - Index - Next |

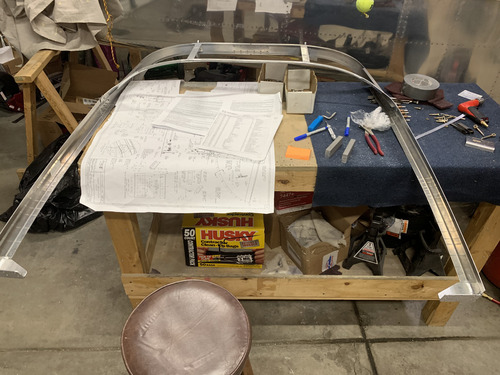

Today I began by removing the frame from the fuselage, deburring, and reassembling on the bench.

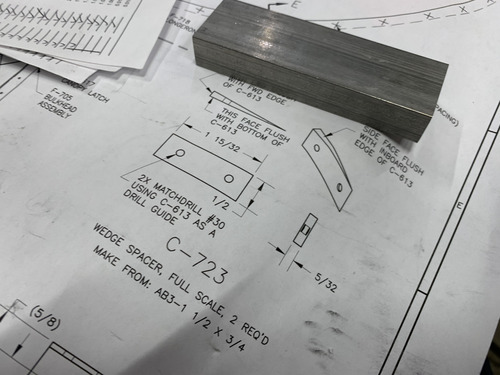

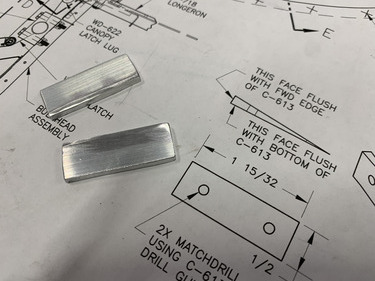

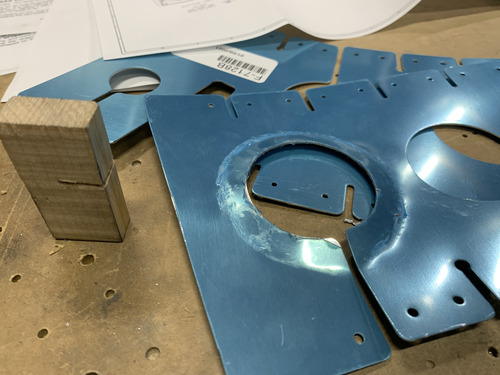

I needed to make these C-723 wedge spacers, which the plans want you to make out of that huge block of aluminum.

Instead, I cut a 3/4x3/4" angle in half and made the wedges out of that.

I cut the wedge shape on the band saw and then sanded them down on the belt sander.

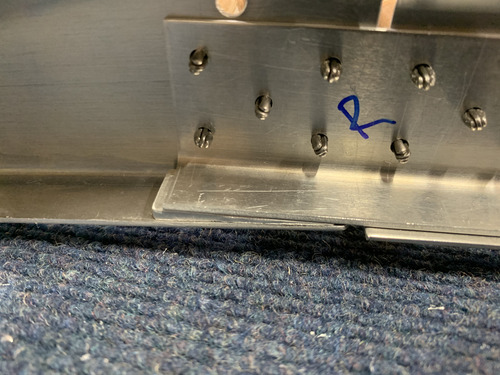

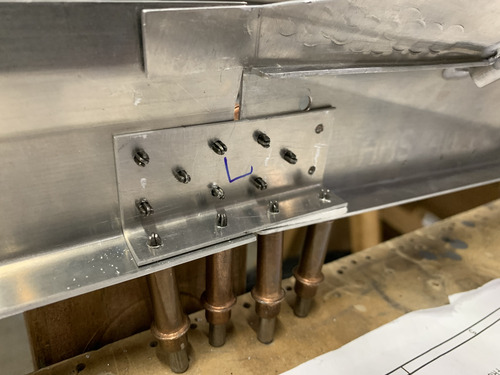

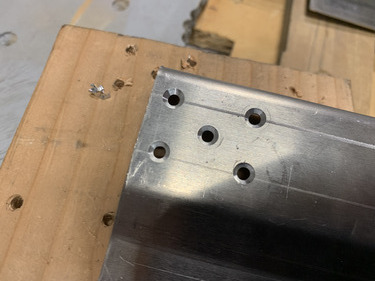

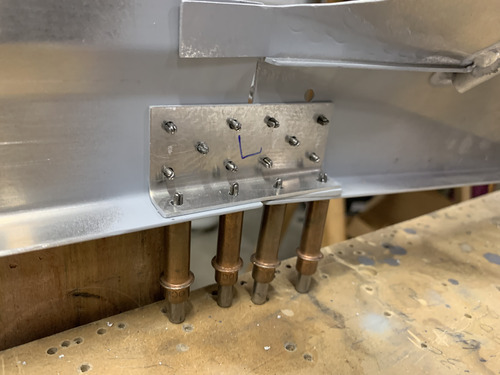

Then, I drilled the C-613 angle to the bottom flange on the WD-725s and WD-716 (both sides).

I countersunk the WD-725s and WD-716 for those flush rivets.

I cleaned and primed all of the mating surfaces.

Then I riveted the WD-725s, C-613s, and WD-716 together, leaving open the little tab on the top.

I cleco'd everything back together on the fuselage and drilled the remaining undersized holes (the forward row and the lateral rows) from the C-702 skin into the WD-716 weldment to full size.

Then I drilled the undrilled holes from the C-702 skin into the WD-716 weldment, except for the one that overlies the C-613. This would interfere with one of the existing rivets. I think I'll just fill this hole with flox and locate another one somewhere that it won't interfere.

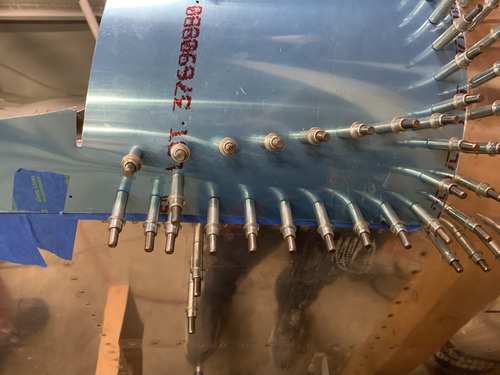

Then, I got out the canopy reinforcement kit and read through the instructions.

I started bending the flanges of the circular cut-outs, except I didn't notice at first I was bending to a 1/2" width rather than 1/4" as specified.

I unbent the 1 1/2 holes I had done the wrong way and then did all 9 holes to the 1/4" distance. These bent flanges give these pieces extra strength, I believe.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International