Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Saturday November 26, 2022

Rudder Bottom Tip Sanding & Filling, Flap Position Sensor

(2.2 Hours

Electrical, 1.0 Hours

Rudder)

3.2 Hours Total

| Previous - Index - Next |

I sanded the epoxy from last time and then applied a thin coat of epoxy to the other side.

There was a small damaged spot on the top cover from the baggage area that I'm patching with a little fiberglass and epoxy/micro.

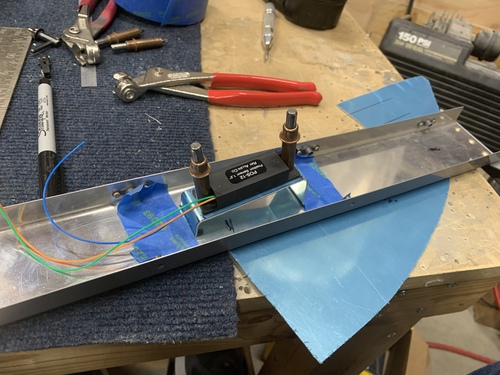

Then I got back to work on the flap position sensor. I fabricated this strap to place around the flap weldment.

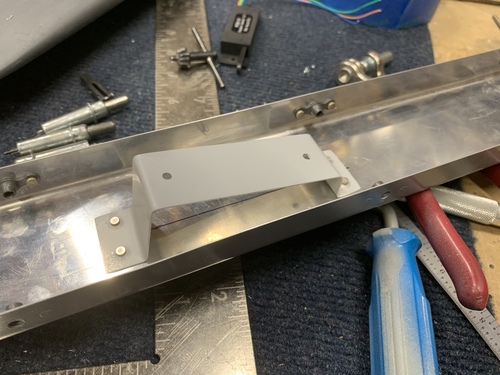

Then I fabricated this bracket to hold the Ray Allen POS-12 sensor at an angle from the rear flap motor cover.

I positioned it and drilled it to the cover.

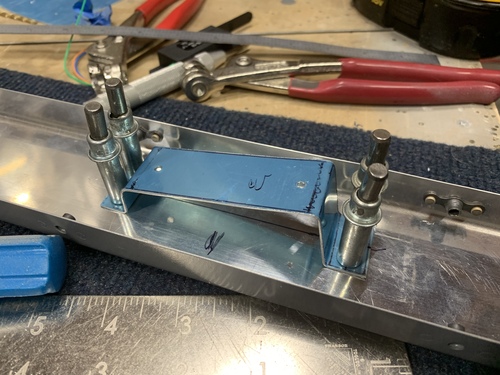

Then I riveted it to the cover.

I decided I wanted #6 nut plates to attach the sensor, so I drilled out the rivets, installed the nutplates, and then re-riveted the bracket to the cover. Here's the POS-12 held in place with some screws into the nutplates.

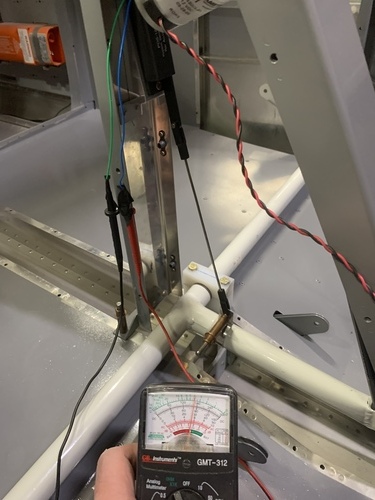

I attached the strap and the sensor together with the RC threaded rod and clevis ends. Here's the whole assembly at the limit of the flap down motion.

And in the flap retracted direction. You can see the change in resistance of the potentiometer in the POS-12. I had to be careful that the motion of the weldment doesn't exceed the motion of the arm in the sensor. With the strap snugged up to the wider section of the weldment toward the bottom, the travel is just about perfect.

Next I'll drill the strap to the weldment to hold it in position. I'm very pleased with how this came out...it was also pretty fun to put together.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International