Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Sunday February 18, 2007

Wing Countersinking, Misc

(Wings)

7.5 Hours

| Previous - Index - Next |

I worked in the shop for a long time today, but I don't feel like I have a whole lot to show for it. I went slowly and carefully while countersinking my main wing spars.

I started by countersinking all of the #8 screw holes in the main wing spars where the fuel tanks will attach.

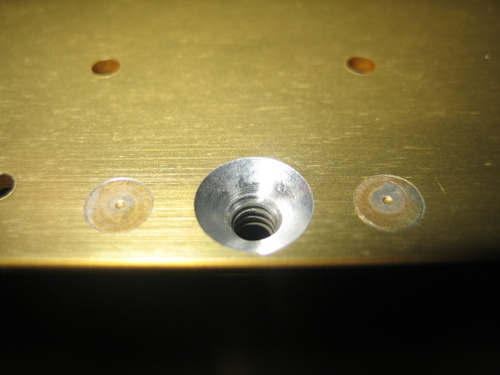

The Vans method (using a #30 countersink bit and having the previously riveted nutplates align the pilot) worked out very well.

Metal shavings like to get stuck in the crevice between the spar and the metal bar that its riveted to, so I taped it off and got the shop vac hose right up by where I was working. This minimizes the mess. There were 120 of these holes to countersink...

There are three removeable access plates on the bottom of each wing and the forward edge of each one screws into the flange of the spar. Here, I've riveted the nutplates that will attach that portion of the access plate to the spar. There are 24 of these between the two wings.

I got out the access plates, smoothed their edges, drilled the holes that attach them to the spar out to #6, deburred, and finally dimpled the holes. I used these to check the depths of the countersinks I did on the spar flange. The other holes in these plates will be for #8 screws.

Next, I countersunk the corresponding holes in the flange of the spar using the #40 countersink bit.

Finally, I riveted these nutplates to the inboard edges of the main spars, as directed. You use flush rivets on the aft side.

Tomorrow is a holiday, so I'm going to take another look at my left elevator and perhaps move on to the next wing related tasks.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International