Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Sunday May 12, 2024

Cowl Installation

(Firewall Forward)

5.0 Hours

| Previous - Index - Next |

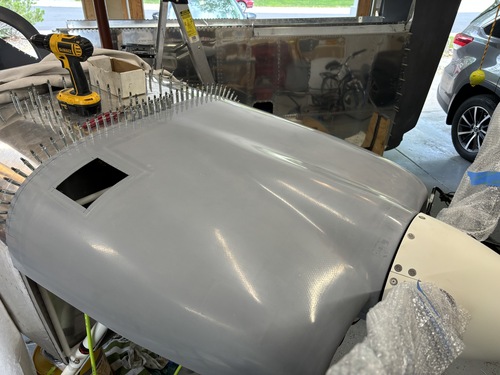

This morning I brought out the engine cowl halves and got to work. First, I cut out the dipstick access door.

Then I worked for a while on getting the fit decent at the front.

Then I drilled the holes through the intake flanges.

Then I started fitting the top half. Notice how nicely it lines up with the spinner, here.

I marked a reference line on the top skin 2" from the edge and then carefully taped the top half in place.

Then I transferred the line to the cowl.

Then I trimmed to that line and drilled holes with 1" spacing.

Then I started drilling into the hinge, checking for alignment constantly.

Yep, it's me doing the work.

Finished drilling the top half to the hinge.

Then I started fitting the bottom half. It took a lot of iterating to make holes for the gear legs.

Then I used reference lines to mark for trimming and made the cuts. Then I marked and drilled holes in the bottom half and drilled to the side hinges.

Finally, I drilled some holes for screws into the bottom support brackets.

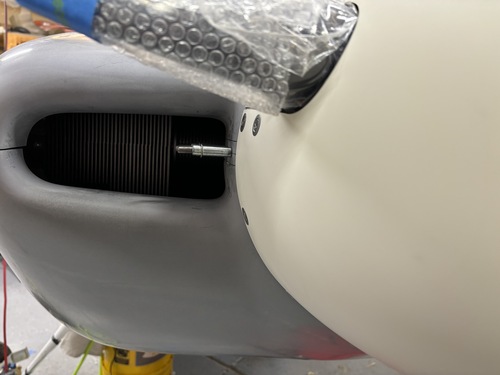

After all of that hard work...the alignment is off. Somehow, despite constantly checking while I drilled, I ended up with the cowl about 1/8" shifted to the left relative to the spinner.

Left side, sticks out.

Right side, flush.

It probably won't make much of a difference at all to performance, but it is very annoying after all of that careful work. Options are to redrill the hinges (not doing that), do a bunch of fiberglass work to the front here to shift things (don't want to do that), or just live with it (probably what I'll do).

Otherwise, it looks really sweet with the cowl in place.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International