Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Tuesday May 14, 2024

Cowl Shifting/Drilling

(Firewall Forward)

3.5 Hours

| Previous - Index - Next |

Last night, I went out and tried to figure out where the problem happened with the cowl alignment. I took off the bottom lower cowl and with just the upper cowl, it was perfectly in alignment. With this knowledge, I put back on the lower cowl and started moving it to see if I could shift things. Sure enough, if I shifted the lower cowl aft on the right and forward on the left, things pulled into a better alignment behind the spinner.

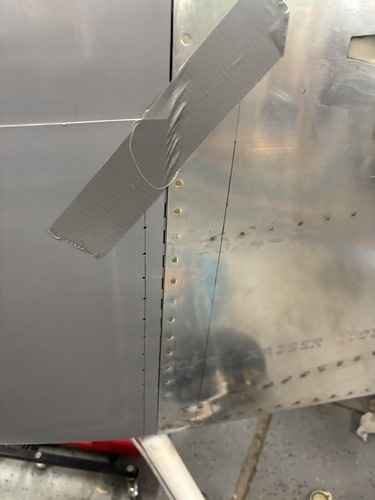

Unfortunately, it makes the sides of the inlets not match up.

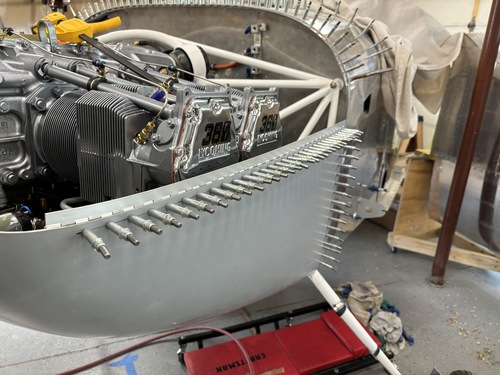

So I slept on it overnight. This morning, I decided to make the change, so I cut another strip off the lower cowl and made a new set of holes for drilling to the hinge.

I drilled new holes into the vertical hinge on both sides and on the bottom of the lower cowl. Then I started fitting the horizontal hinge pieces to the lower cowl.

Drilled on the right side.

And on the left.

Then I started drilling it to the upper cowl on the left side.

I will have to fix this on both sides. It will require some build-up with fiberglass and a lot of sanding, but I will make it look good.

Then I drilled the horizontal hinge to the upper cowl on the right side.

This is so much better! The cowl is still a little bit shifted to the left, but it's much harder to see now than it was before. I am very happy with this.

I will sand down the inboard side of the left-hand inlet a bit just to make it even less noticeable.

I'm really happy that I was able to make this better--it was really bothering me. The only cost will be some extra time fixing the inlet mismatch and adding a little more fiberglass to the aft end of the lower cowl on the left side. Worth it.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International