Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Friday May 24, 2024

Top Cowl Inlet Ducts, Oil Door

(Firewall Forward)

4.2 Hours

| Previous - Index - Next |

Today, I put another coat on the wheel fairings. A little sanding and these should be done.

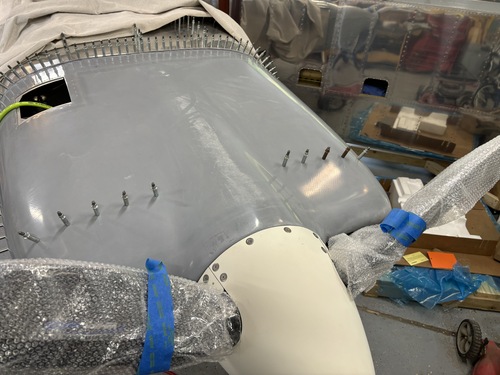

I trimmed the inlet ducts so I could move them forward and then drilled them to the top cowl. This will hold them in place while epoxy cures and holds them in place.

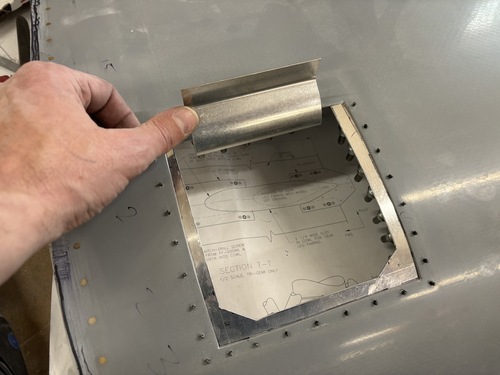

Then I got to work on the oil door. I bought a hinge system from Aircraft Spruce that hides the hinge underneath rather than the plans method where you can see it. I trimmed off the recessed fiberglass.

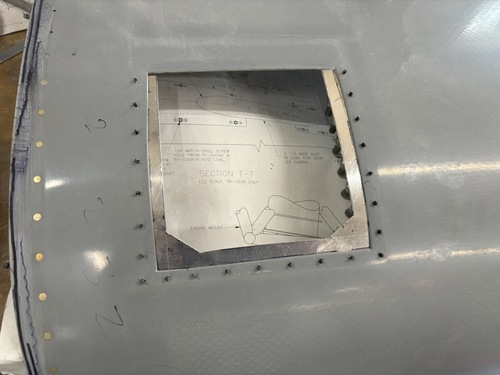

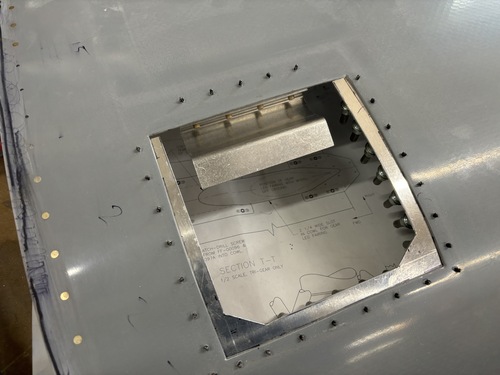

Then I cut a recess out of a scrap of aluminum sheet.

I had to trim back a little of the border of the honeycomb on the cowl to give it enough overlap with the cowl.

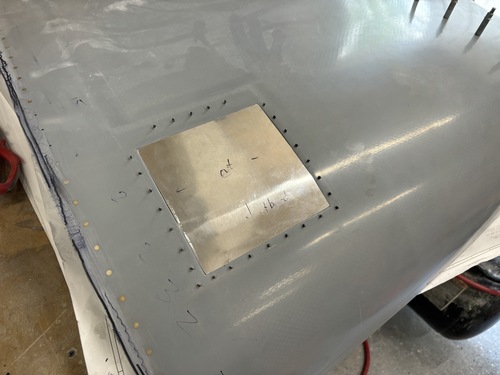

Then I drilled it to the cowl.

I also drilled the hinge to the cowl. This is the closed position.

And this is open. It comes with some springs to make it pop open when the camlocs are released.

I fabricated an oil door from scrap aluminum--I've heard that the fiberglass version that comes with the cowl bows out during flight.

I drilled the oil door to the hinge and drilled two holes at the bottom for the camlocs that keep it closed.

Then, I riveted the recessed bracket and the hinge to the the cowl with some epoxy/flox as adhesive. I also covered the areas where I had trimmed into the honeycomb with epoxy/flox.

I also epoxied the inlet ducts into place with the clecos holding them. I then reinstalled the cowl so it's in the right position while the ducts cure in place. Evidently they give it some significant stiffness.

I also riveted the other hinge half to the oil door.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International