Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Sunday September 15, 2024

Starter/Alternator Wiring, Ignition Wires, Inlet Seals

(Firewall Forward)

6.2 Hours

| Previous - Index - Next |

I realized I had a big bag of size 5 adel clamps already and swapped the two out on the starter and alternator wires.

These were a pain to tighten. I also realized that I forgot that I want the shunt (for measuring amps) between the alternator and the alternator fuse on the firewall, so I may need to re-do that wire.

I got out the ignition wires and, with the help of the P-MAG manual, routed them to the plugs. I used zip ties to hold them in place, but for final securing, I'll use adel clamps and lacing cord.

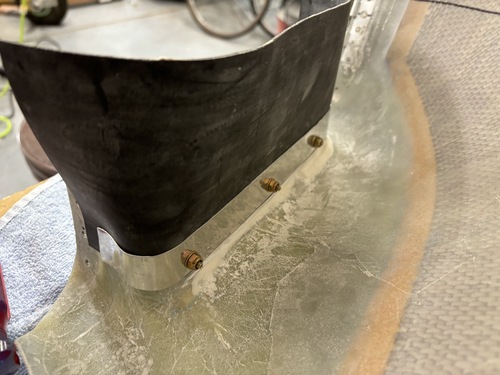

Then, I got back to work on the baffle seals for the inlets. I made these pieces of aluminum sheet bent to match the shape of the underside of the inlet.

Then I drilled them and some air seal material to the inlet bottom.

The metal serves to clamp the air seal material in place. I purposely grossly oversized the air seal material initially.

Then I installed the lower cowl and marked the air seal material for trimming.

I cut to the trim line and then reinstalled. This will work pretty well.

There are a couple of wrinkles that I need to deal with, but overall I'm pretty happy with the seal on the inlets. I think it's going to work well.

I also spent some time trying to figure out how I'll plumb the manifold pressure line to the P-MAGs. I ordered a 1/4 NPT to 1/4 barb fitting to go in the pressure manifold and then I'll run the silicon/rubber tubing that came with the P-MAGs to a "tee" with 1/4 barbs on it to split out to both of them. The ignitions use the manifold pressure to help determine proper ignition timing.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International