Log (By Day)

Log (By Category)

Pictures

Pics of Me Working

Links

| ||||||||||||

Saturday August 9, 2025

Draining Preservative Oil, New Oil Filling, PMAG Timing & Testing, Prop Tracking, Engine Pre-Oiling, Fuel Plumbing

(0.8 Hours

Center Fuselage, 4.0 Hours

Firewall Forward)

4.8 Hours Total

| Previous - Index - Next |

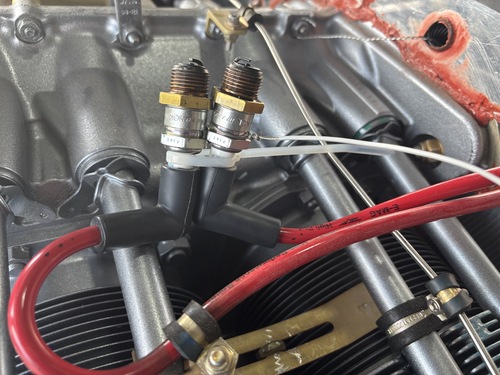

I started today by draining the preservative oil out of the engine cylinders. Here's cylinder #2 draining from the lower spark plug. I used some plastic bags to try to avoid oil getting all over everything.

Cylinders 2 and 4 both had oil, but neither 1 or 3 had any to drain. Not sure why. I moved the prop through several cycles, just to be sure.

Then I programmed the PMAG ignitions to my desired timing (about 7 degrees past TC). They seem to have been programmed at Lycoming to about 4 degrees past TC.

Then I did the pull-through test with the spark plugs all removed and grounded. Pulling through roughly TC fires 1 and 3 and roughly 180 degrees past that fires 2 and 4.

I did one PMAG at a time and all eight spark plugs fired appropriately. That means I wired them all correctly!

Then I drained the oil sump from both sides to get the rest of the preservative oil out of the engine.

While I was waiting for the oil to drain from the sump, I unpacked my little pancake air compressor and charged it up. Then, I pumped the tires up to about 40 PSI.

I also checked for appropriate propeller tracking. All three blades tracked within about 1/16-1/8"--closer than the 1/4" required by the manual.

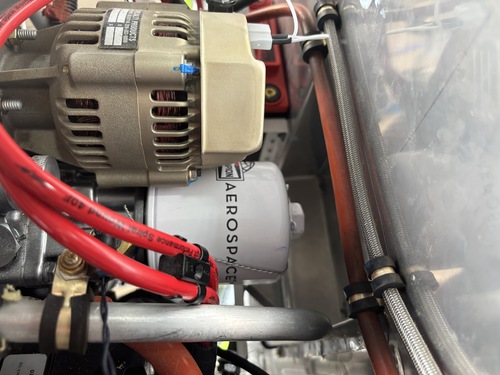

I also changed the oil filter--it honestly looks like the one that was on there was brand new, though. There was no oil in it.

Then I filled the sump with about 7L of new oil.

Then, I disconnected the plane from the power supply and connected it to the battery.

Next, I pulled off the top spark plugs and ran the starter until I got oil pressure, per the Lycoming instructions for pre-oiling the engine. I ran the starter motor for a maximum of 10 seconds at a time, allowing a few minutes in between for it to cool. It took about 30 seconds of total running for oil pressure to develop. This means that oil has been pumped through the whole engine and is ready for the first engine start.

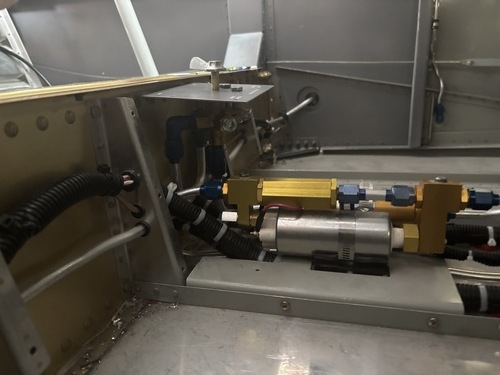

Then I got the fuel plumbing in the cockpit all connected again. I don't like how low the fuel selector plate is sitting relative to the spar flange. I think I need to bend the fuel tubing a bit more.

| Previous - Index - Next |

This work is licensed under Attribution-NonCommercial-NoDerivatives 4.0 International